Impulse heating bands and heating band connections

Impulse heating bands and heating band connections

Heating band cross sections for sealing and perforating:

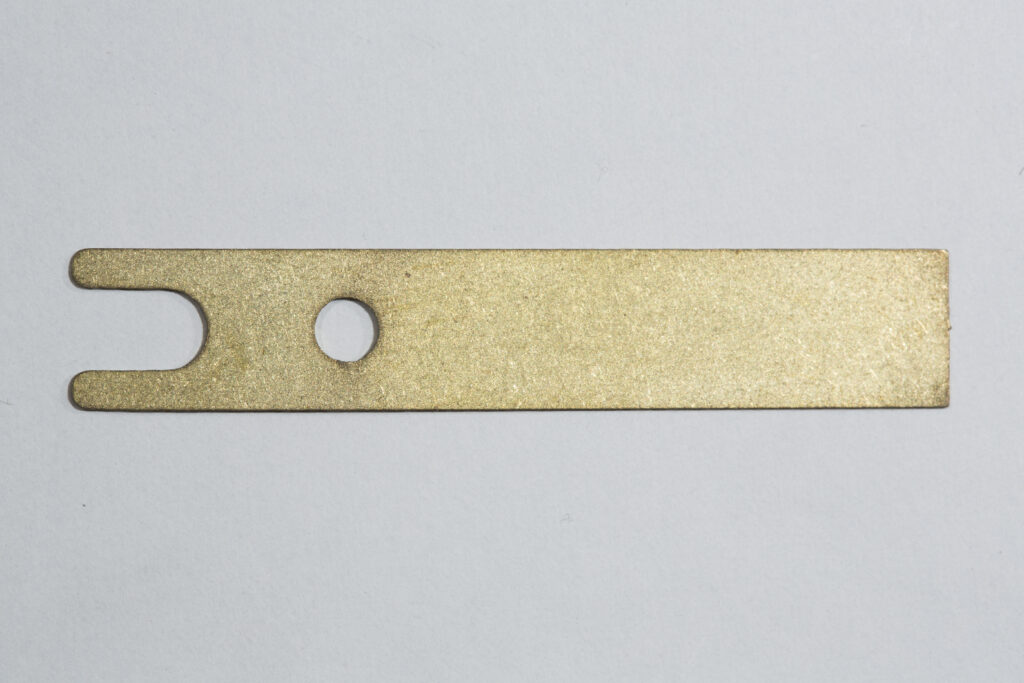

Flat Band

Standard sealing, strong weakening of the seam edge

Tapered band

Standard sealing, minimum weakening of the seam edge

Reflex band

Vacuum packaging, low bar pressure

Double seam band

Vacuum-liquid packaging, particularly safe seam

Drilled Wire

Perforation seam, tear-off seam

Pulse band cross sections for cut sealing:

Beaded band

Cut sealing, standard cutting of the seam separation in the seam

T-profile

Cut sealing, standard cutting of the seam separation in the seam

Triangular profile

Cut sealing for thick foils, best seam

Cutting wire

Cut sealing, narrow seam, minor stability

Half-round profile

Cut sealing for thick foils

All strip cross-sections produced by us can be ordered by the meter as well as assembled.

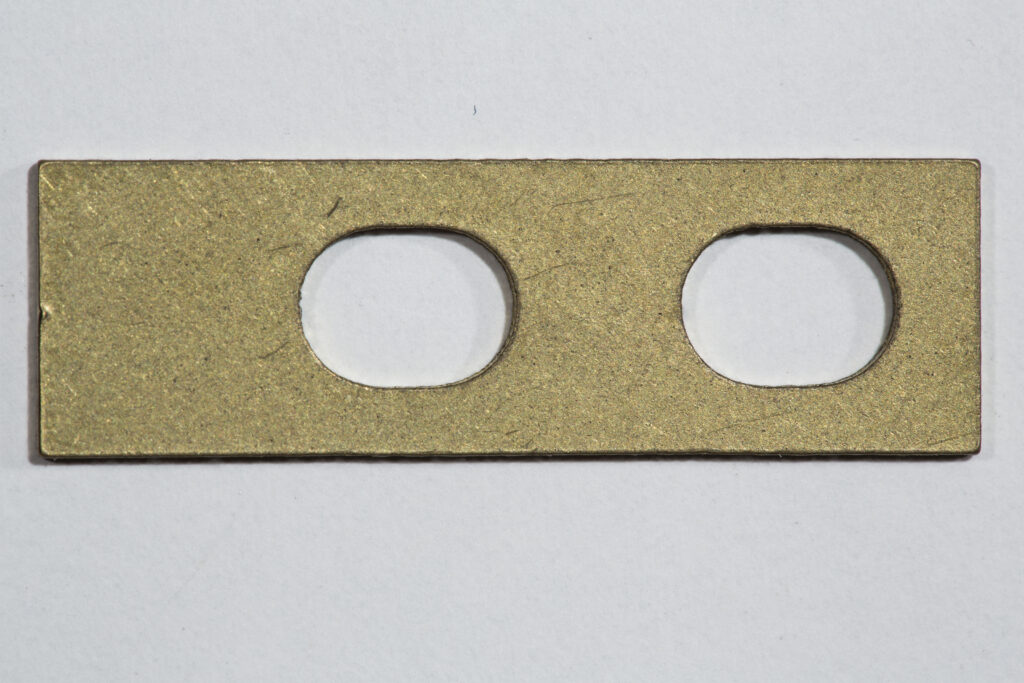

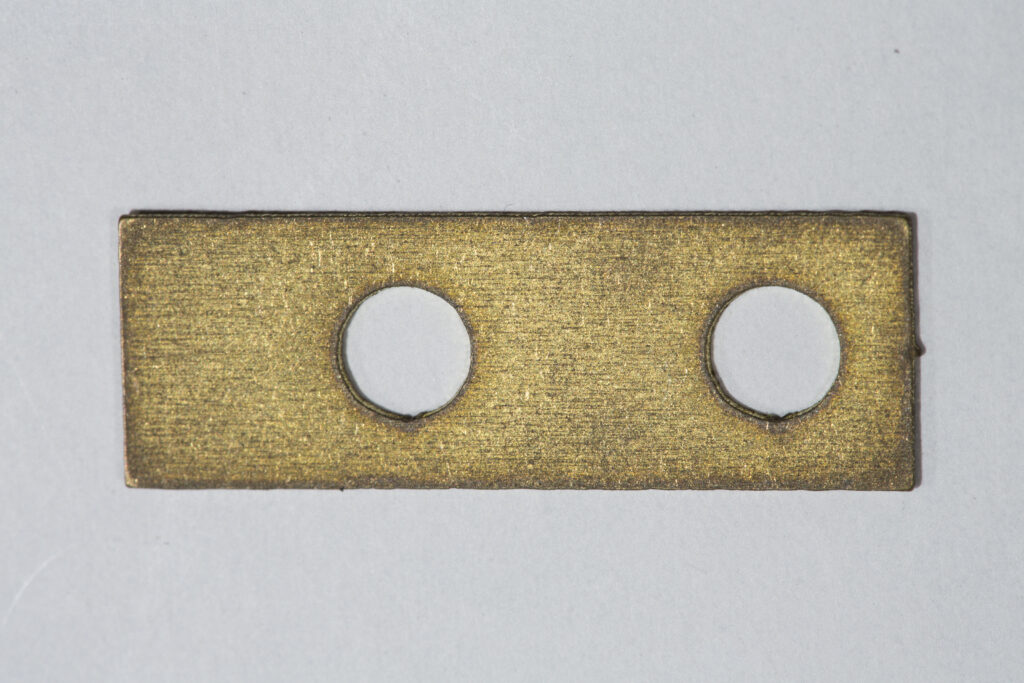

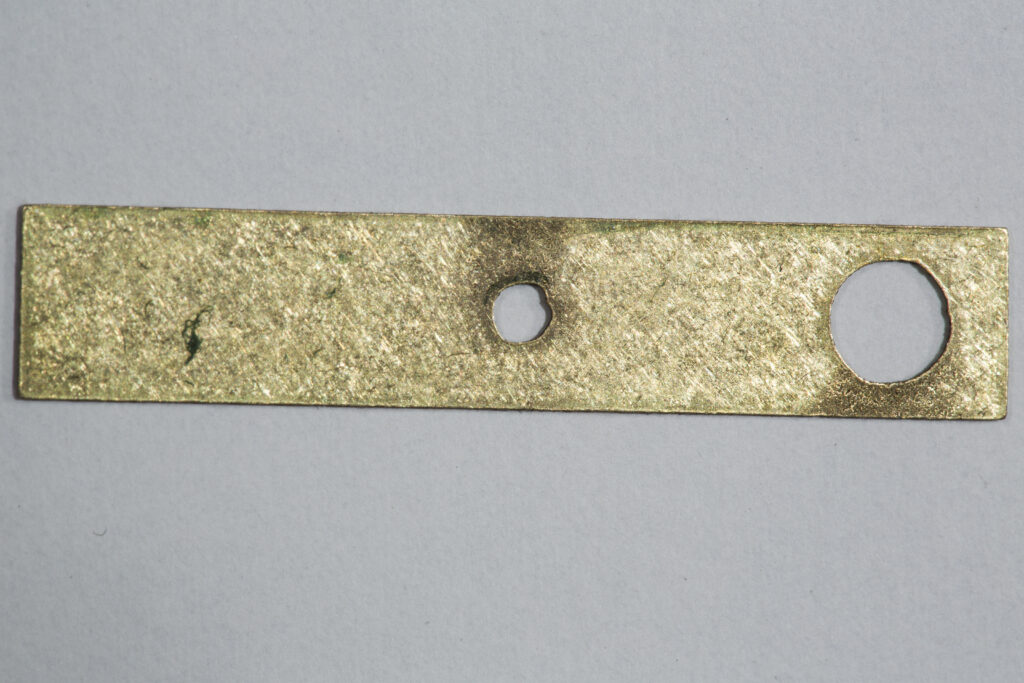

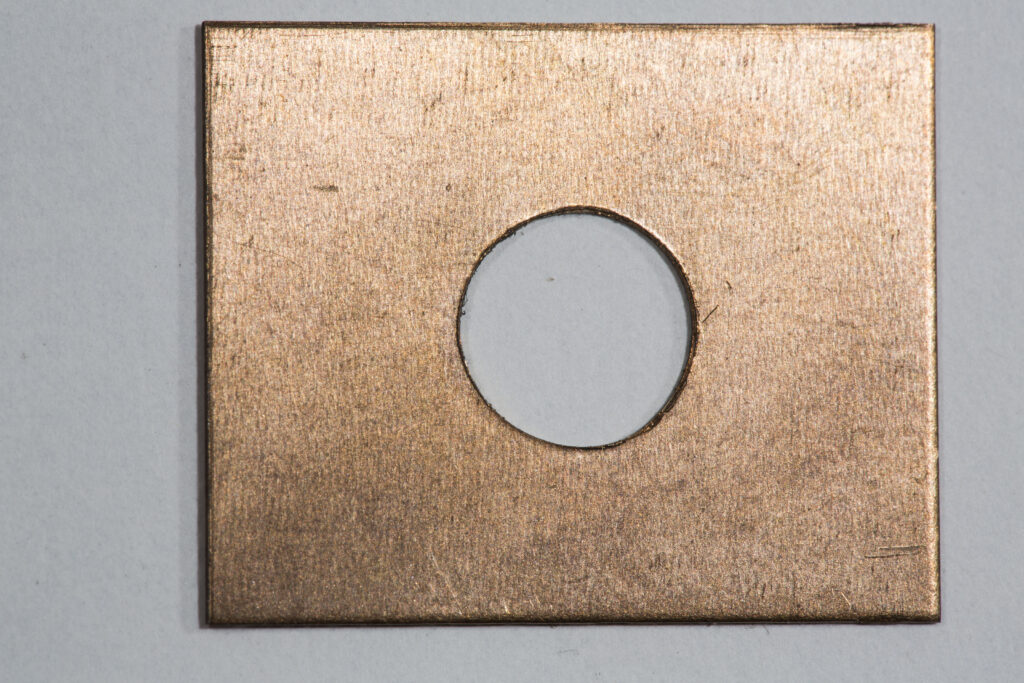

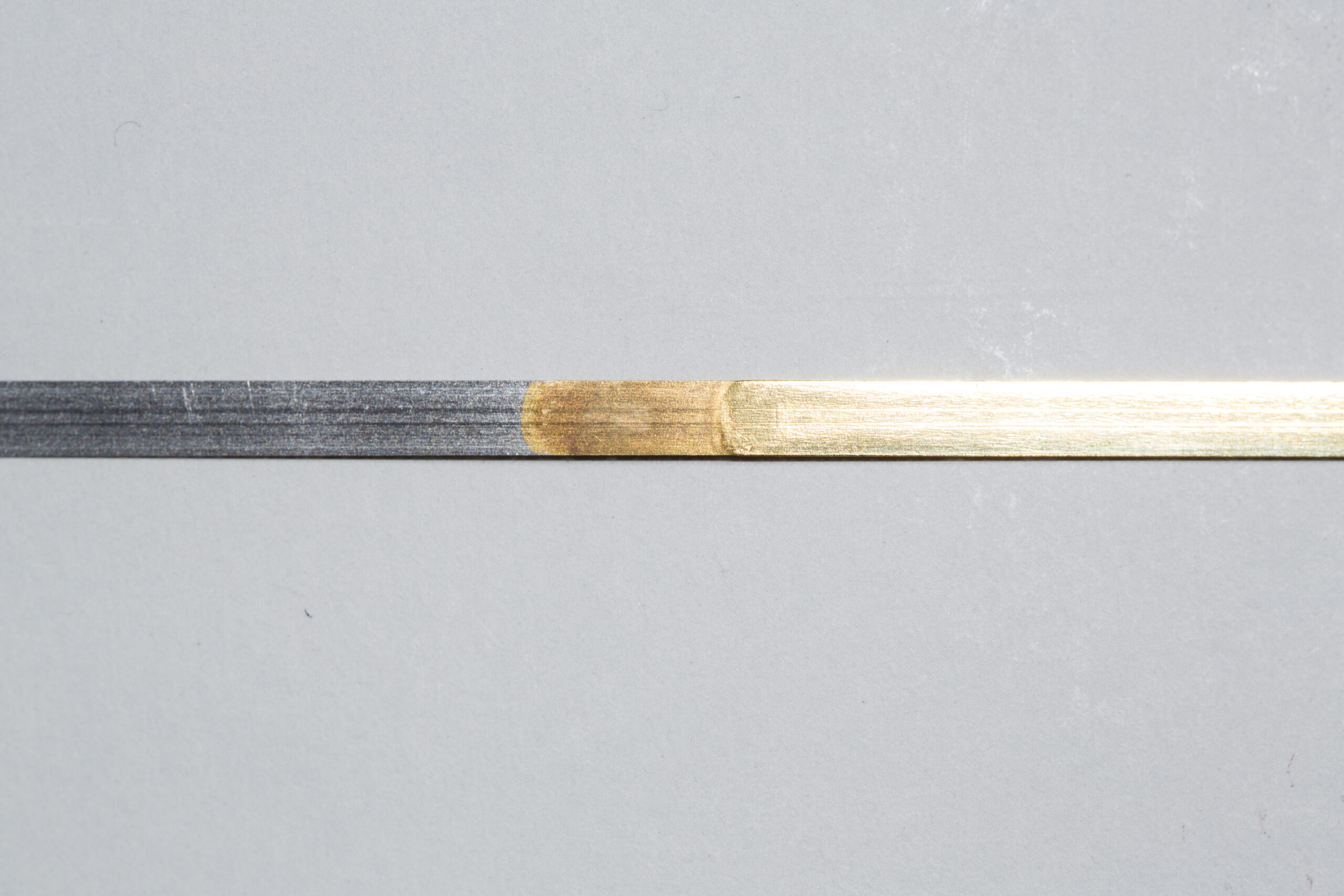

The pre-fabricated bands can be equipped with copper-plated, nickel-plated, gold-plated, silver-plated ends and heating band connections. If required, the bands can be coated with PTFE.

Your contact persons:

Manfred Schemken

- Film welding technology manager

- anfrage@prewa.de

- +49 (0) 6408 90 46 15

Thomas Hössler

- Deputy manager of film welding technology

- anfrage@prewa.de

- +49 (0) 6408 90 46 23

PTFE coatings + refinements :

All ready-made sealing bands can be manufactured with the following coatings:

Copper plated

Nickel-plated

Silver plated

Gold plated

PTFE green

PTFE gray

PTFE black

Silverstone black